[ad_1]

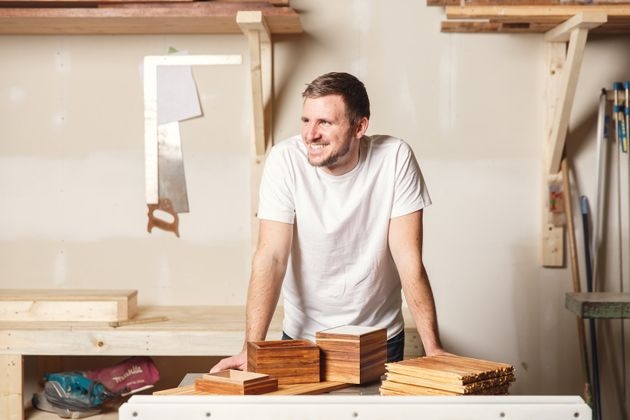

Trying to address the immensely small and intolerably overlooked problem of toothpick waste, a BC resident created a startup that recycles used toothpicks into custom-made furniture and other useful items like tablet holders.

In 2016, Felix Böck, a doctoral student at the University of British Columbia’s college of forestry, estimated that 100,000 pairs of toothpicks were sent to landfills in Vancouver alone each day.

Now in its fourth year, ChopValue has exploded in success. Böck employs 40 people, and using its special steam methods and pressing machines, has recycled 32 million pairs of toothpicks.

Armed with a mindset of German engineering and Canadian sustainability, Böck created not only a flourishing business, but a new production model for a circular economy.

The furniture and other items you create like shelves, cutting boards, coasters, and decorative hexagonal blocks often contain thousands of toothpicks per item – a good thing, as billions of toothpicks are used each year throughout the Western Hemisphere.

Evolution of chopsticks

Classical Chinese historians recorded chopsticks to be known and used before the Shang dynasty, which would place them 5,000 years in the past. Historian Q. Edward Wang states in his book Chopsticks that the tool was of Neolithic origin and perhaps it was also used to stir food in pots.

An article of Treehugger Interestingly it suggests that it was the semi-mythical founder of the Xia Dynasty, Da Yu, who used two twigs when, in his rush to get to a particular place, he needed to avoid boiling water from his food and eat immediately.

In a similar epiphanic moment, one news report suggests that Böck and his girlfriend came up with the idea while eating at one of Vancouver’s many sushi restaurants.

Contemplating the extent of toothpick waste (80 billion is thrown away every year in China alone) and a little push from his girlfriend, he began to convince restaurant owners to install recycling bins exclusively for toothpicks.

PLUS: The new green building revolution uses wood to build ‘scrapers’ that save tons of CO2

Once collected, they are coated with resin and pressed into blocks. Hundreds of restaurants in North America pay Böck a small fee to recycle their used chopsticks.

CHECK OUT: Stanford designer is making bricks with fast-growing fungi that are stronger than concrete

Böck hopes to scale his business model by expanding factories to recycle local wood such as toothpicks around the world without relying on supply chains, something he calls Microfactory, and which he has established in 10 countries.

SHARE the good green news with friends on social media …

[ad_2]

source material