[ad_1]

Given that the construction industry is the biggest generator of waste in Paris and elsewhere, what can be learned from the new ‘biological house’ in the French capital?

In the extreme southeast of Paris, in the shadow of the 1950s, the concrete-laden Olympic towers, is an experiment conducted by what is perhaps NASA, or even Charlie’s Eco-designed Chocolate Factory.

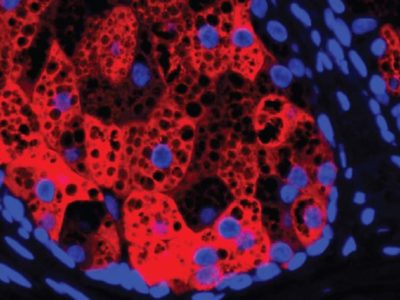

Within 228 square meters there is an oak staircase made from 80 recycled doors, digital radiators heated as a by-product of the computer processors within them, and 16 hyper-efficient solar panels that filter and ventilate the building’s air, as well as producing electricity. The structure is made almost entirely of “bio-based” materials, which grow naturally, such as wood and straw.

Known as The little factory (the Little Factory), Paris city council officials hope that this innovative prototype can help the French capital meet its commitment to become carbon neutral by 2050. As building construction is the main source of waste in Paris, With 9.5 million tons of garbage a year and 20 percent of the city’s greenhouse gas emissions, it is seen as a sector with enormous potential for improvement.

“It’s a huge waste,” says Nathalie Chazalette, who, along with architect Delphine Paillard, leads a small publicly funded research and development team called the Ecological Transition Gateway. “We want this project to inspire all construction companies to do the same. We want them to at least reach this level of sustainability, but, if possible, even more ”.

Every inch of the two-story Little Factory, which launched in late 2020 as two school libraries and a classroom, exudes extraordinary attention to detail. The insulation consists of 225 bales of straw on the walls and a 25 cm layer of recycled cardboard on the floors, resting on 39 reusable steel piles, which produce 50% less CO2 than concrete, nailed to the ground. Bladeless fans hang from the ceiling like spaceships, creating a Covid-safe 360-degree ventilation vortex, while low-tech triple-glazed windows keep the interior temperature balanced by slowly filtering the air.

Part of the wood for the structure comes from the Bois de Vincennes public park, a few kilometers away. The upstairs deck will feature an orchard, and the patio asphalt has been removed and replaced with “vegetated” living floor tiles that are part mineral and part grass, which soak up excess rain.

The structure is made almost entirely of materials of “biological origin”, such as wood and straw. Image: Ville de Paris

Chazalette and Paillard’s motto is to “build differently” in a very practical sense, using eco-friendly materials and taking advantage of the strengths of the circular economy. The bricks that make up the interior wall and plaster, for example, are made from raw earth collected by drilling holes for the Grand Paris Express transportation project. They were brought together by a team of 17 refugee women from Les Bâtisseuses, a charity that trains refugee women in green building to help them integrate into society.

“There is nothing like it,” says Chazalette. “But we did not come up with all these innovations. Our innovation was putting together all of the incredible work that we discovered throughout our research. “

The project was officially launched in September 2018, but construction of the biological house did not begin until a year later. Instead, the team’s initial focus was intensive research. Studies were carried out on the microclimate of the site to measure variables such as wind, sunlight and rainfall, leading to design adaptations such as wooden sunshades that can be extended over the windows to counter excessive heat. At the same time, Chazalette traveled to various projects in France, including Rosny-sous-Bois, Brittany, and the Loire Valley to learn from the crème de la crème of French green building.

We want this project to inspire all construction companies to do the same

The result of such attention to detail is a building that contains no concrete and weighs only 196 tons (compared to an estimated 1,300 tons if conventional materials had been used). Just 60 tons of material will not be compostable or recyclable, such as laminated glass and moisture barriers on the walls, and the building will be largely powered by renewable energy. However, the € 510,000 (£ 447,000) budget to create the structure, which had already been decided before Chazalette and Paillard’s green team took on the project, remained exactly the same.

While France is already a world leader when it comes to modern, bio-based construction, as of 2022, for example, all new public buildings. should To be built with at least 50% wood or other natural materials: the Little Factory is the first project of its kind carried out by public authorities in Paris.

The bricks for the building were made from raw earth by a team of refugee women. Image: Ville de Paris

One of the few disappointments was that the exterior walls were built with Siberian larch wood to meet fire safety regulations because fast-growing local alternatives burn out too quickly, according to Chazalette. Heavy rains last October also caused leakage problems amid construction and the team was unable to obtain insurance to use certain recycled materials they wanted. But she believes the only real limit to expanding this model is the time it takes for suppliers of “bio-sourced” materials to build capacity.

“This is the first step to mobilize the sector, to show that it is possible,” says Chazalette. “This experiment was to learn from any problem we encountered so that others would have the solution.”

Referring to Paris’ carbon neutral pledge, he adds: “Now we have to make it happen, that’s what the politicians voted for.”

Main Image: City of Paris

[ad_2]

Original source